Headstage Cables

Plexon offers a wide variety of headstage cables to connect any Plexon headstage to its compatible amplifier/processor. We offer a choice in wire size to more closely match your needs. Additionally, several specialized cable wraps are available and can be applied to protect your investment from animal bites or other damage. Plexon is committed to the success of your research and is happy to manufacture the cables – wire, lengths, connectors, wraps and configurations – to meet your needs.

Headstage cables are available in a variety of options including: wire gauge, cable wraps, lengths, connectors and configurations. The proper build will improve the quality of your recordings as well as protect your investment. All Plexon headstage cables are reusable.

Wire Gauge

Standard 34 gauge

The standard gauge for headstage cable wire used by Plexon is 34 gauge which is flexible, yet robust. 34 gauge wire is ideal for head-fixed experiments, or for research in which the freely behaving animals are unlikely to be impeded by the cable. The standard 34 gauge wire is easy to identify as the wire insulation is multi-colored.

Ultra-fine 36 gauge

If your experiments require small animals such as mice,

If your experiments require small animals such as mice, we recommend our 36 gauge ultra-fine wire. This thinner cable wire is lighter-weight and is less likely to impede the behavior of smaller animals. Additionally, digital headstages exclusively use 36 gauge wire. The ultra-thin wire is also easy to identify as it has white wire insulation.

Cable Wraps

Unless otherwise requested, headstage cable wires are bound using tiny shrink-wrap cuffs spaced approximately every 1.0 to 1.5 inches (shown in the images above). There are situations, however, in which the standard cuffed method may not be sufficient: if the cables may be snagged during normal use, damaged by biting animals, or if you wish to increase the cable torque transmitted to a standard, non-motorized commutator for more effective operation. In these circumstances, we recommend one of the following wraps. The wraps are presented in order of increasing strength, weight and protective qualities. All wraps are available for all cables.

Polyester Mesh Wrap

polyester mesh wrap is the lightest-weight and most flexible wrap Plexon offers. It will protect the headstage cable from damage incurred due to general use such as snagging, and is light enough and flexible enough for use with small animals, such as mice. This wrap is recommended for use on ultra-fine 36 gauge wire cables, and if working with small animals.

polyester mesh wrap is the lightest-weight and most flexible wrap Plexon offers. It will protect the headstage cable from damage incurred due to general use such as snagging, and is light enough and flexible enough for use with small animals, such as mice. This wrap is recommended for use on ultra-fine 36 gauge wire cables, and if working with small animals.

Clear Plastic Wrap

The next step up in strength is the clear plastic wrap. It provides some additional benefit over the polyester mesh wrap with respect to protection from damage incurred during standard use, and is slightly stiffer. The clear plastic wrap is especially beneficial if your experimental set-up includes a non-motorized, Standard Commutator. A plastic-wrapped headstage cable will transmit torque to the commutator better than an unwrapped or polyester mesh-wrapped headstage cable will.

The next step up in strength is the clear plastic wrap. It provides some additional benefit over the polyester mesh wrap with respect to protection from damage incurred during standard use, and is slightly stiffer. The clear plastic wrap is especially beneficial if your experimental set-up includes a non-motorized, Standard Commutator. A plastic-wrapped headstage cable will transmit torque to the commutator better than an unwrapped or polyester mesh-wrapped headstage cable will.

Metal Mesh Wrap

The metal mesh wrap is stronger yet. It will provide protection from standard use damage, transmit additional torque to a non-motorized commutator, and offer a minimal degree of protection from animal bites. The metal mesh wrap provides additional protection beyond that of the previous options.

The metal mesh wrap is stronger yet. It will provide protection from standard use damage, transmit additional torque to a non-motorized commutator, and offer a minimal degree of protection from animal bites. The metal mesh wrap provides additional protection beyond that of the previous options.

Metal Coil Wrap

The metal coil wrap is our strongest, most robust wrap. It will transmit torque to t

The metal coil wrap is our strongest, most robust wrap. It will transmit torque to the non-motorized commutator and protect the headstage cable from animal bites and other damage. It is especially beneficial when experimental subjects are likely to become bored or quite agitated, such as with substance abuse research in which the animals become aggressive.

Cable Lengths

Headstage cable length is defined as tip-to-tip including the connectors. Plexon’s headstage cables have a default length of 36 inches and can often be cut to custom lengths. The technical specifications table will identify our most popular headstage cables with options. These are cables that we stock in inventory and are able to turn around very quickly. We do produce many cables beyond what is outlined in the table. We are happy to discuss any custom requirements that you may have or variations to what is provided to meet your needs.

Output Connectors

The headstage cables are specifically designed to connect to the headstage output connector. For maximum versatility, several headstages have been designed utilizing the same output connectors. The technical specifications table will help guide you through identifying the appropriate cable based on knowing the headstage.

Configurations

Straight Cables

The vast majority of cables requested are simple, straight cables in which there is one connector on each end, such as the photo on the top of this page.

Y-Cables

Occasionally, a bifurcated cable is necessary, such as with an experiment recording neural data bilaterally. Any straight cable we manufacture can also be manufactured as a Y-cable.

Occasionally, a bifurcated cable is necessary, such as with an experiment recording neural data bilaterally. Any straight cable we manufacture can also be manufactured as a Y-cable.

To compliment your headstage cables, Plexon offers a variety of headstages, connectors and commutators to support your research. Contact a Plexon Sales Engineer for more information or to discuss your specific needs.

The table below provides a listing of the most commonly ordered straight headstage cables based on headstage; however, we can produce custom cables beyond what is listed below – including the transforming the straight cables into Y-cables. The most advantageous combinations of connectors, headstages and headstage cables for your specific research can be best determined with the assistance of your Plexon Sales Engineer.

| Headstage* | Headstage Specs | Cable Wire Type | Wraps*** |

A | Pitch: 0.050” Channels: 8, 16, 24 HST/8o50-Gx-xR HST/16o50-Gx-xR | Cable: HSC/8 Cable: HSC/16o50 Analog 34 gauge Analog 36 gauge | None, Polyester mesh, Clear plastic, Metal mesh, and Metal coil. |

C2 | Pitch: 0.025” Channels: 8 HST/8o25-GEN2-9P-G1-xR | Cable: HSC/8 Analog 34 gauge Analog 36 gauge | None, Polyester mesh, Clear plastic, Metal mesh, and Metal coil. |

D2 | Pitch: 0.025” Channels: 8 HST/8o25-GEN2-10P-G1-xR | Cable: HSC/8 Analog 34 gauge Analog 36 gauge | None, Polyester mesh, Clear plastic, Metal mesh, and Metal coil. |

E2a | Pitch: 0.025” Channels: 16 HST/16o25-GEN2-18P-2GP-G1 | Cable: HSC/16o25-GEN2 Analog 34 gauge Analog 36 gauge | None, Polyester mesh, Clear plastic, Metal mesh, and Metal coil. |

E2b | Pitch: 0.025” Channels: 16 HST/16o25-GEN2-18P-6GP-G1 | Cable: HSC/16o25-GEN2 Analog 34 gauge Analog 36 gauge | None, Polyester mesh, Clear plastic, Metal mesh, and Metal coil. |

| F3 | Pitch: 0.025” Channels: 32 HST/32o25-GEN3-36P-G1 | Cable: HSC/32o25-GEN3 Analog 34 gauge Analog 36 gauge | None, Polyester mesh, Clear plastic, Metal mesh, and Metal coil. |

H2 | Pitch: 0.025” Channels: 16 HST/16V-G20 LN (Legacy Item) | Cable: HSC/16V Analog 34 gauge Analog 36 gauge | None, Polyester mesh, Clear plastic, Metal mesh, and Metal coil. |

| J2

| Pitch: 0.025” Channels: 32 HST/32V-G20 LN (Legacy Item) | Cable: HSC/32V Analog 34 gauge Analog 36 gauge | None, Polyester mesh, Clear plastic, Metal mesh, and Metal coil. |

| J3

| Pitch: 0.025” Channels: 32 HST/32V-G20 LN 5V (Legacy Item) | Cable: HSC/32V Analog 34 gauge Analog 36 gauge | None, Polyester mesh, Clear plastic, Metal mesh, and Metal coil. |

L | Pitch: 0.050” Channels: 8 HST/8o50D Gen2 | Cable: HSC/DHSC1 or HSC/DHSC3 (black wrapped cable)

| None, Polyester mesh, Clear plastic, Metal mesh, and Metal coil. |

M | Pitch: 0.025” Channels: 96 HST/CereStage 96 | Cable: HSC/CereStage 96-H42F-36G Cable: HSC/CereStage 96-2H26F-36G Analog 34 gauge Analog 36 gauge | None, Polyester mesh, Clear plastic, Metal mesh, and Metal coil. |

| N

| Pitch: 0.049” Channels: 8 HST/8-BIOP-PNS | Cable: HSC/8-BIOP Analog 34 gauge | None, Polyester mesh, Clear plastic, Metal mesh, and Metal coil. |

| P

| Pitch: 0.049” Channels: 8 HST/8-BIOP-EDIF | Cable: HSC/8-BIOP Analog 34 gauge | None, Polyester mesh, Clear plastic, Metal mesh, and Metal coil. |

Q2 | Pitch: 0.025” Channels: 16 HST/16D GEN2 | Cable: HSC/DHSC1 or HSC/DHSC3 (black wrapped cable) | None, Polyester mesh, Clear plastic, Metal mesh, and Metal coil. |

R | Pitch: 0.025” Channels: 32 HST/32D | Cable: HSC/DHSC1 or HSC/DHSC3 (black wrapped cable) | None, Polyester mesh, Clear plastic, Metal mesh, and Metal coil. |

T | Pitch: 0.025” Channels: 16 HST/16D GEN2 DIFF | Cable: HSC/DHSC1 or HSC/DHSC3 (black wrapped cable) | None, Polyester mesh, Clear plastic, Metal mesh, and Metal coil. |

S | Pitch: 0.025” Channels: 64 HST/64D | Cable: HSC/DHSC2 or HSC/DHSC4 (black wrapped cable) | None, Polyester mesh, Clear plastic, Metal mesh, and Metal coil. |

ST | Pitch: 0.025” Channels: 12 HST/12-NLT | Cable: HSC/12-NLT-36L | None, Polyester mesh, Clear plastic, Metal mesh, and Metal coil. |

U | Samtec connector, thumbtack design Channels: 64 HST/64DS | Cable: HSC/DHSC2 or HSC/DHSC4 (black wrapped cable) | None, Polyester mesh, Clear plastic, Metal mesh, and Metal coil. |

V | Samtec connector, thumbtack design Channels: 128 HST/128DS Gen 1 | Cable: HSC/DHSC2 or HSC/DHSC4 (black wrapped cable) | None, Polyester mesh, Clear plastic, Metal mesh, and Metal coil. |

V2 | Samtec connector, thumbtack design Channels: 128 HST/128DS Gen 2 | Cable: HSC/DHSC2 or HSC/DHSC4 (black wrapped cable) | None, Polyester mesh, Clear plastic, Metal mesh, and Metal coil. |

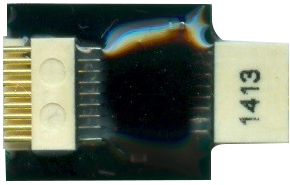

*Image size: Please note that the product images above are not to scale relative to either actual size or to each other.

**Information in the table represents the most commonly ordered headstage cables – and are likely to be available in stock. However, you are not limited to only the options presented. Almost any cable can be produced using either 34 gauge or 36 gauge wire. Additionally, most cables can produced at any length, although generally there is little need beyond 132 inches. Please plan additional manufacturing time for custom cables.

***Wraps can be applied to any cable of any length. However, cables over 72 inches require special attention and may take a bit longer to produce.